Part Number for filename? What are the benefits?

It is very surprising to me that more tool and die companies don’t work with part numbers as the file name as opposed to the name of the part (the description, really) as the file name. I think the reason they don’t is because when most companies start out using 3D CAD, they start by naming the file “Die Block.sldprt” because that just seems more natural than just a number, and that is why some of them still do it this way years later. Also, it is intimidating (at first) to look at a folder full of numbers as file names as opposed to a folder full of “names” as file names. But once you are used to this, it is intimidating to look at a folder full of names as opposed to orderly numbers.

Of course the rest of the world works with part numbers typically rather than names. For example: If you buy anything at all for your home or car or whatever, and you need to order a new part, you look at the diagram of parts and most of the time you look at the balloon that is pointing to the component you need and look to see that this balloon is pointing to part number 12345 or whatever and you order a 12345. Or perhaps there is simply a part number being called out with a leader.

I believe there are two really significant benefits to using a part number (such as 17033-006 where 10733- is the project number or job number and 006 is the part number) for the file name rather than a descriptive name:

Benefit #1:

Many if not most dies cannot be designed fast enough for management - they want to get steel on the floor and start cutting… So there is typically a problem because the BOM is not done yet and so you don’t know what the detail number is going to be, assuming you want your balloons in the correct order, etc, but of course you’d like the steel you order to be identified in some way. Using a part number allows you to order material based on the job # and part # combination and this part number is determined the minute before the designer puts the part into the assembly. So even if the part isn’t finished yet, you know what size it is and what kind of material, etc…

Benefit #2:

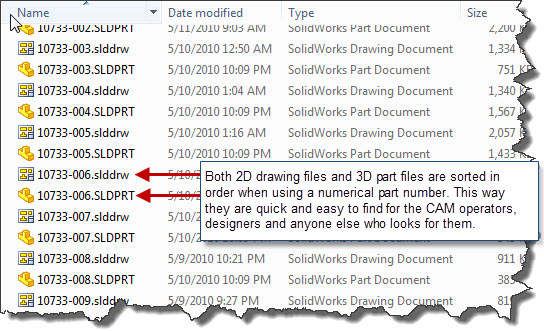

Back when we were using 2D, it was a major pain to have each detail on its own drawing – this often meant having each detail drawing as its own file. But today, with 3D and in particular with LogoPress, it is far easier to have each detail on its own drawing and being its own file. In addition, with all parametric modelers, including SolidWorks, each part file is its own separate file and these separate files go into an assembly. So it is much easier to locate these files in a folder or directory if they are in some sort of order. Giving the files a part number rather than a descriptive name brings this order to Windows Explorer and this way the CNC CAM operators and the WEDM operators and everyone else can find the files much more easily, as you can see from the picture below.

Benefit #3:

Having sheet numbers is just not necessary anymore in most cases, unless you need to keep doing it because “We’ve always done it that way“. We are creatures of habit, and sometimes this is the reason we do still do things like we did years ago. Instead of sheet numbers, many folks just use the part number of the part as the “sheet number”, so to speak. It’s not actually called the sheet number because you don’t look for sheet 22, you look for part number XYZ…

I would encourage you to look at the possible benefits of using part numbers as file names rather than the description of the part for the file name. I will detail instructions for an easy method of doing this using LogoPress in the next post or two.

Topics

- -IMPORTANT-1- info for LP users

- -IMPORTANT-2- info for LP users

- LP 123GO Light

- LP 123GO Full

- LP How-To's for users

- LP Standard Components

- LP tips & tricks

- LP Unbending

- LP Warning messages

- SolidWorks tips & tricks

- General tips & tricks for all

- Windows tips & tricks

- A great use for WAX (stretch webs)

- Computer performance

- Computer benchmark

- Software we use

- FREE software

- Uncategorized