Stampack Forming Simulation Software

Stampack is the practical forming simulation for every tool designer. This means:

- Straightforward and clear user guidance

- The user of Stampack does not need any previous knowledge about finite elements methods and material science.

- Stampack is affordable for every design department and engineering office.

Stampack allows designers and method planners to simulate forming processes for prototype, progressive die and transfer die tools. The combination of shell and solid simulation in Stampack allows versatile applications. The component spectrum ranges from aluminium foils with a thickness of 0.01mm to formed parts with a sheet thickness of 6mm. Typical products simulated with Stampack are:

- Automotive body in white parts

- Trim panels, covers and trim strips in vehicle interiors

- Connecting components and support plates

- Electrical connectors and cable guides

- Metal containers, cans, lids and caps

- Boxes for electrical, household and hydraulic appliances

- Household utensils such as baking trays, cake tins and kitchen sinks

- Heat shields and aluminium foils

Stampack Includes Two Solvers:

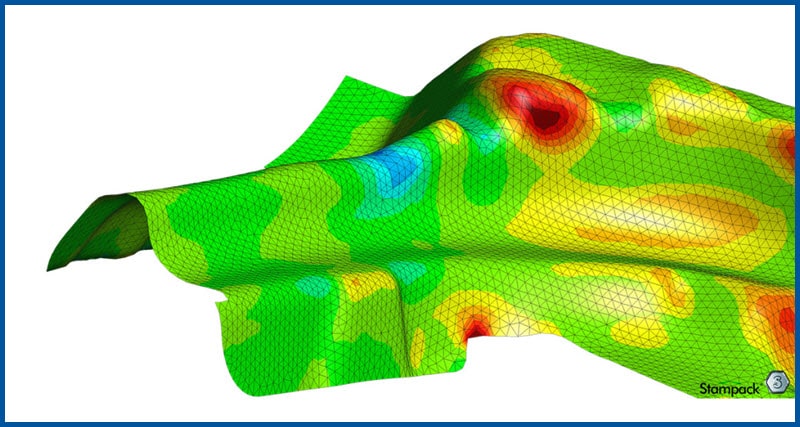

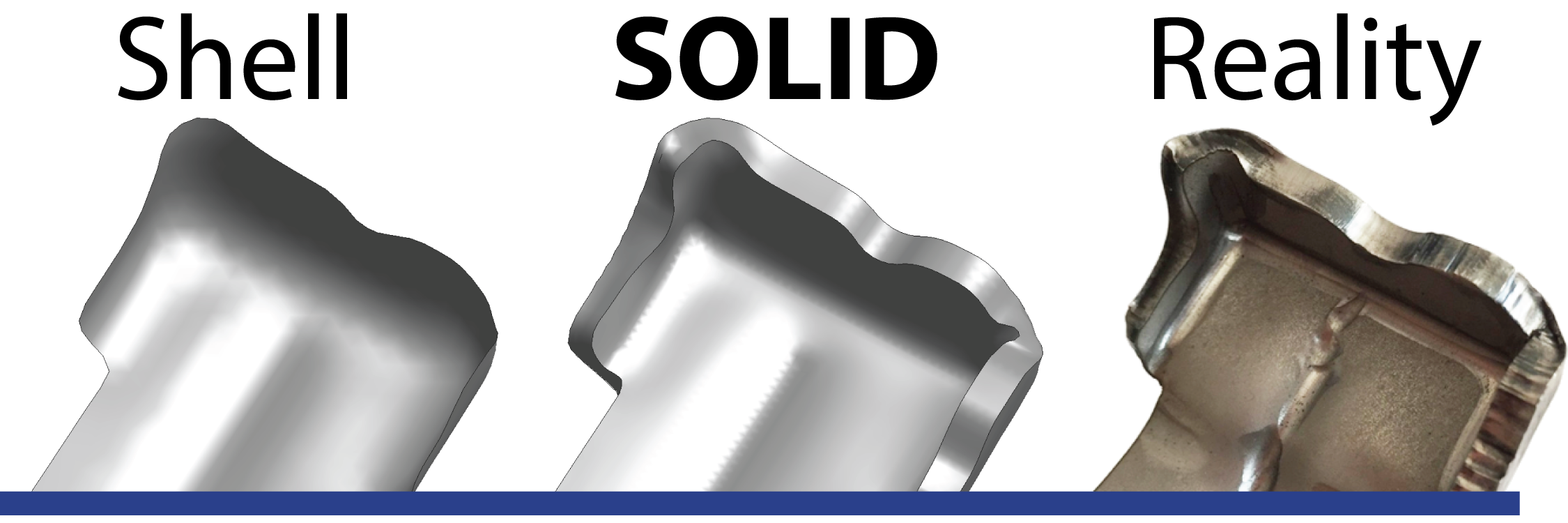

Stampack Shell Simulation

With the Shell module, Stampack offers the possibility to accurately reproduce forming processes with thin-walled sheets and large drawing radii. Due to the short calculation time, shell simulation is an industry standard in forming simulation and is widely used especially in the automotive industry. Even with thicker sheets, shell simulation is suitable for calculations and for a useful first impression. Learn More

Stampack Solid Simulation

Stampack uses solid simulation to reproduce the forming process with maximum accuracy. Forming processes with thick sheets, small radii or reduction of material thickness can only be validated reliably with solid simulation, as considerable stresses and strains occur in the thickness direction. Learn More

Expand Stampack with these add-ons:

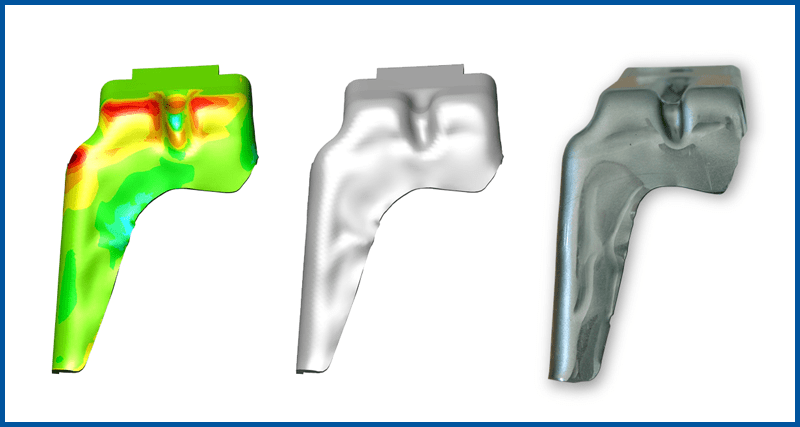

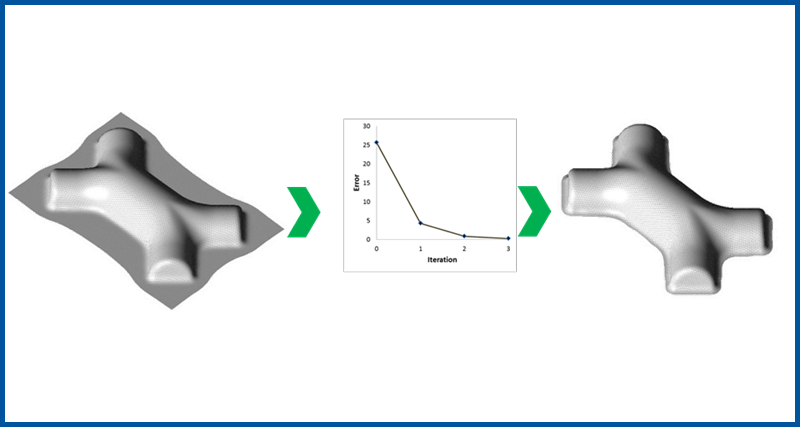

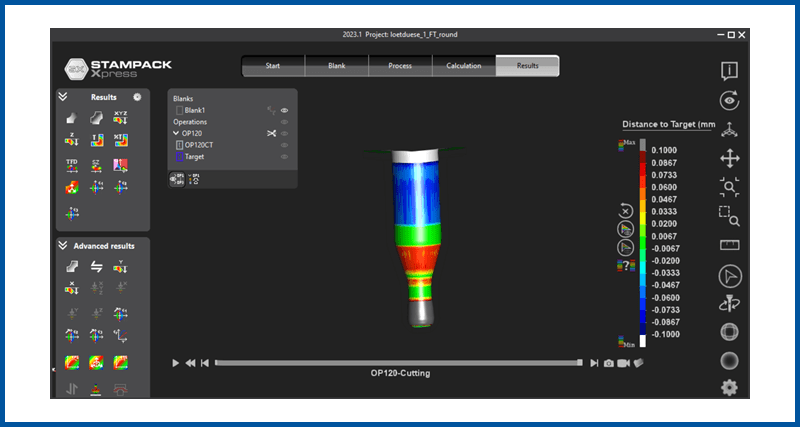

Measure and Optimize Toolbox

Accurately simulating the forming process is a huge first step, but adjusting the cutting and forming tools to create a part within tolerance is where the real time savings come from. Learn More

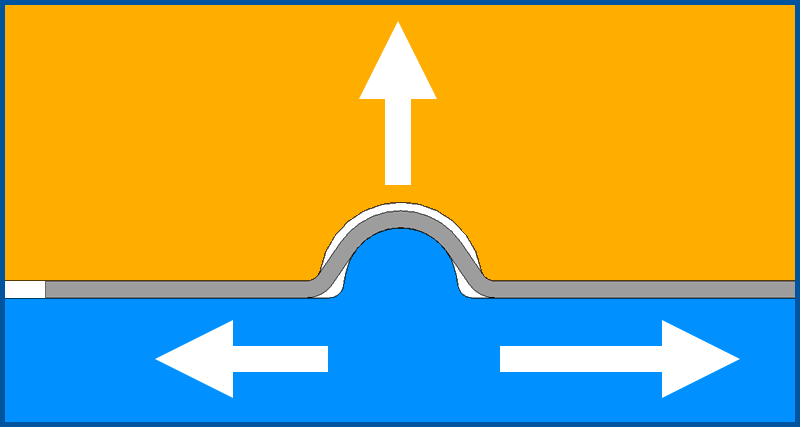

Drawbead Tool

Calculate drawbead shapes and simulate them significantly faster as compared to adding physical draw beads to imported tooling surfaces. Learn More

Stampack Results Viewer

A FREE tool to view Stampack Simulation results without the need for a seat of Stampack. Learn More

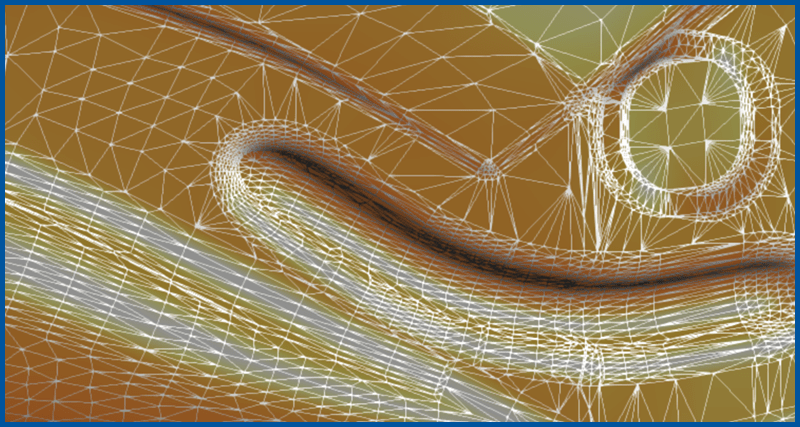

Import2Mesh

Import2Mesh imports CAD-Data, repairs it automatically and generates for the simulation optimized meshes.

Import2Mesh options include: Catia, NX, Creo, or Parasolid files. Learn More