LogoPress ProgSim

Software for Forming Simulation and Automatic Blank Development inside of SOLIDWORKS and LogoPress DieDesign or DieDesign PREMIUM software.

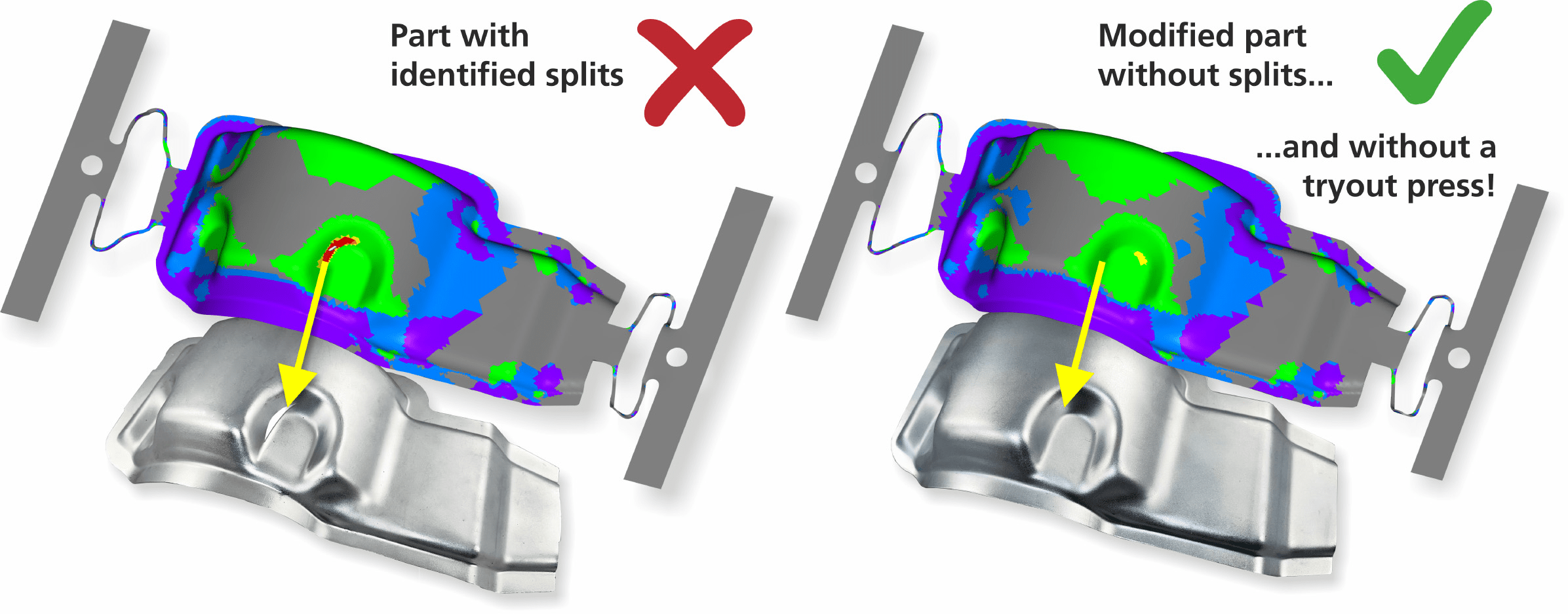

Simulate, Modify, and Validate Strip Layouts on your Computer Screen to Prevent Costly Time in the Tryout Press and Subsequent Rework Costs

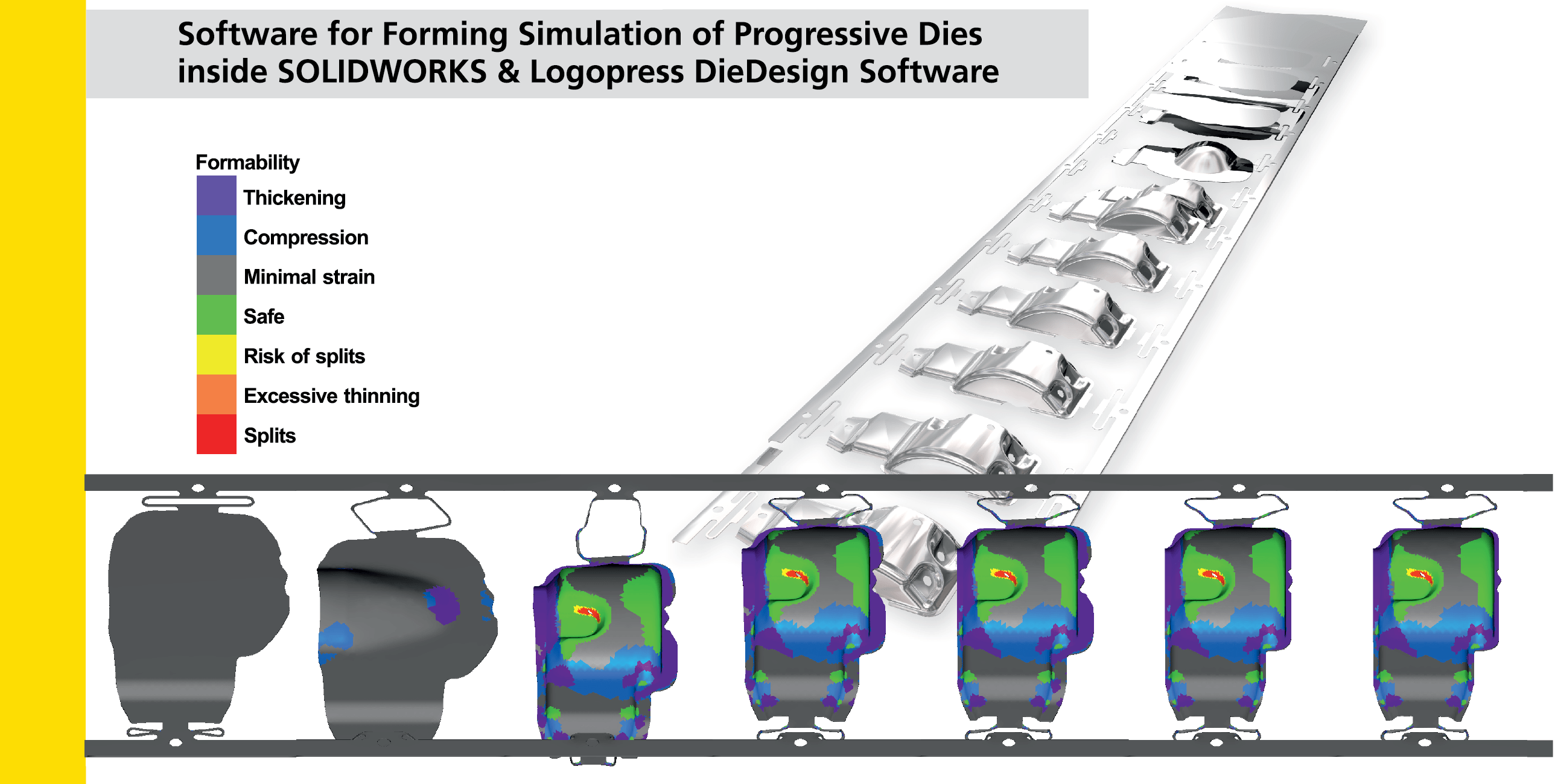

LogoPress ProgSim enables progressive die designers working in SOLIDWORKS to efficiently simulate, modify, and validate their strip layouts. The software allows them to gain deep insight into the forming process and take corrective measures on the computer screen to prevent costly prototyping and/or trial and error in the tryout press.

- Accurate forming simulation of progressive dies based on an incremental approach

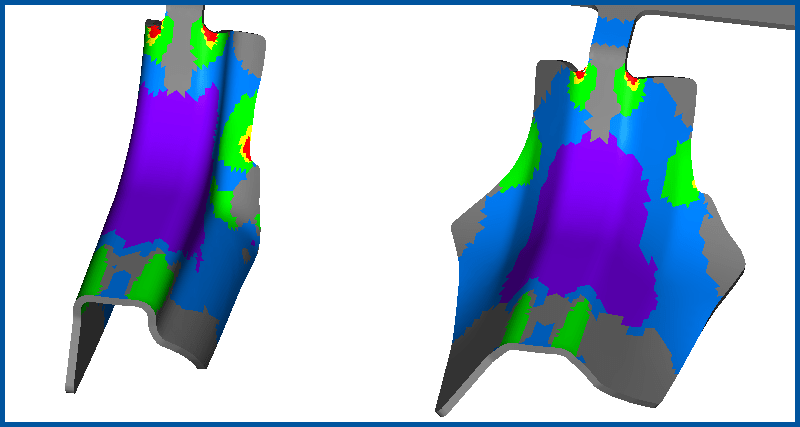

- Discover and address formability and springback issues during the strip layout/die design stage

- Important feedback on key stamping quality issues, such as wrinkles, splits, and excessive thinning

- Faster, more accurate, and more profitable delivery of progressive dies

- Multiple ways of displaying accurate springback results

- New: includes automatic blank development with Cut Optimizer

- Very affordable, easy to use, and highly accurate virtual tryout press, customized for small to medium sized stampings

LogoPress ProgSim allows progressive die designers rapid and accurate forming simulation of the progressive die process including drawing, flanging, and forming operations, as well as springback. They can gain deep insight into the forming process, including force prediction, and can quickly identify problem areas such as wrinkles, splits, or excessive thinning that might occur during the process.

With LogoPress ProgSim, die designers—even without any prior FEA experience—can get all of the relevant results necessary to evaluate and make changes as necessary to the process. The software acts as a virtual tryout press for forming and enables die designers to validate a process quickly and accurately even before the actual die design has begun.

This knowledge of the forming process— discovered on the computer screen—expands the overall formability know-how of the entire design department and can be shared with estimators as well as die makers to expand their knowledge.

Die designers can move forward with a die design whose process is already proven. This reduces time and costs related to prototyping and time spent in the tryout press and leads to a consistently faster and more profitable delivery of progressive dies.

Watch videos here:

ProgSim - A Virtual Tryout Press

Stop wasting time and money in the tryout press. Get forming results in SOLIDWORKS using real tooling to identify formability or springback issues as well as optimize cutting geometry. Watch Videos Here