Virtual Drawbead Simulations

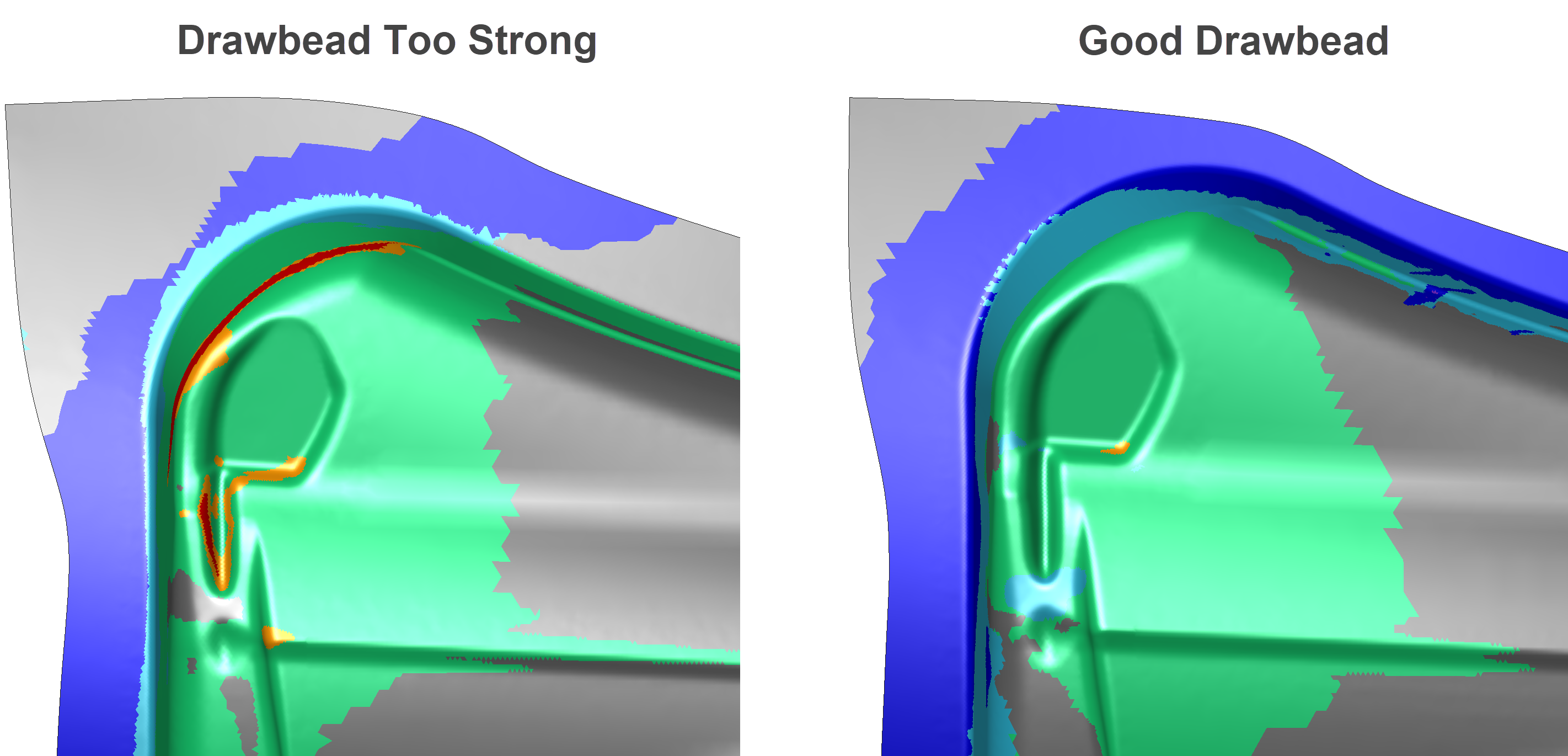

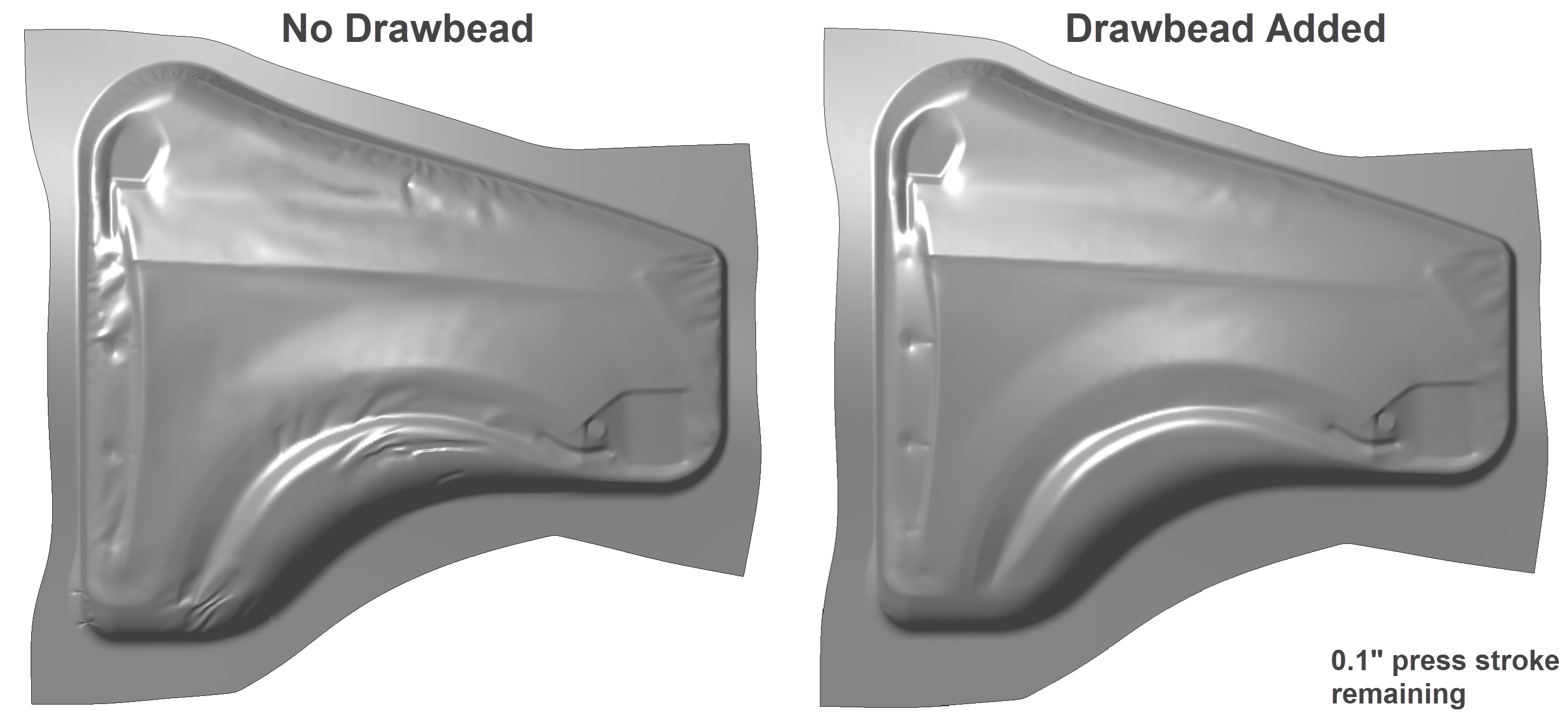

When stamping with large thin sheets, the material will tend to wrinkle and cause the final part to have an undesired surface or material folds. To prevent this, drawbeads are used which typically consists of a gusset like shape surrounding the formed area of the sheet. This geometry will help restrict the material and better control the flow of the sheet into the die cavity. This can help reduce wrinkling, splits, and removes the need for having a much higher blank holder pad force that would otherwise be needed to reduce the wrinkling.

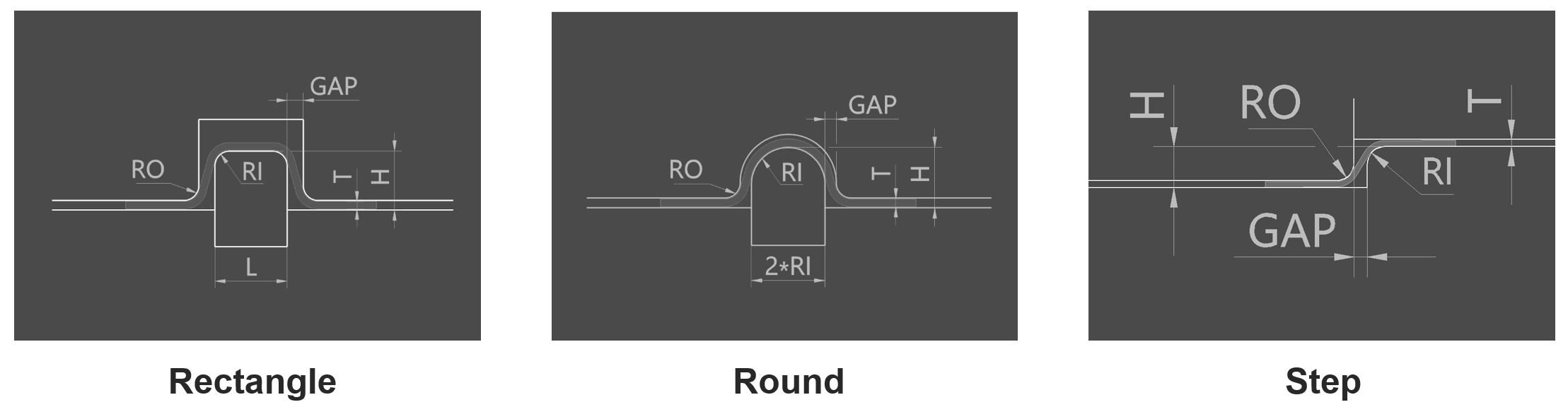

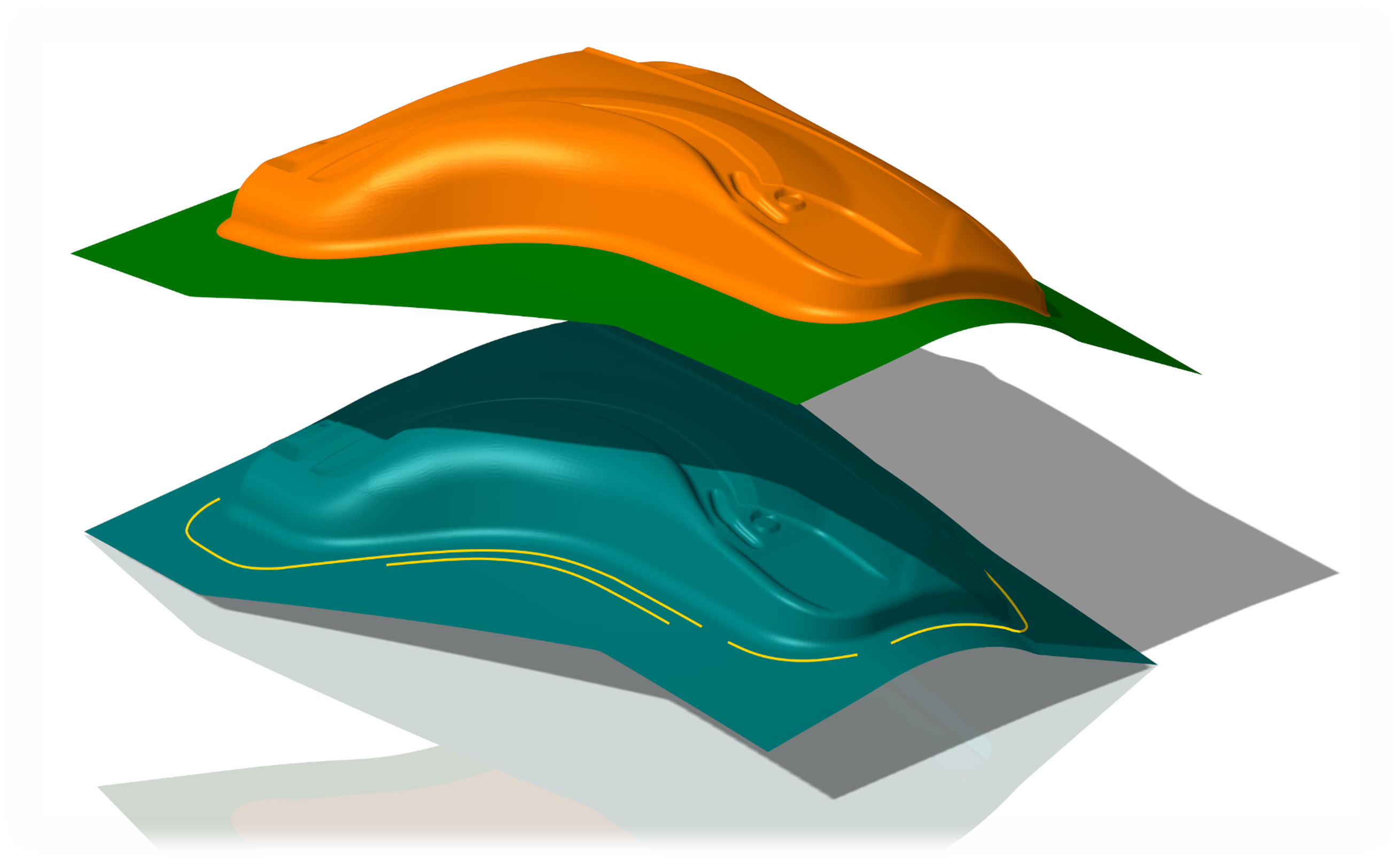

Drawbeads can vary in their shape and sizes, and when paired with complex and curved geometry, this can make designing the drawbeads in CAD very time consuming. With Stampack's Virtual Drawbead add-on, there are 3 different drawbead shapes included where you can freely change their size and shape and to specify their locations on the form tools. This greatly speeds up the process of testing out different parameters in order to find the optimal combination that gives the best results after forming.

By simulating the drawbeads virtually rather than physically, this will also greatly increase the speeds of the simulation, giving you the results you need in the fastest time possible. This will allow you to find the perfect drawbead setup that will reduce wrinkling and prevent splitting. A must-have option for anyone developing stamping processes for large panels!