Logopress3 Advanced

Logopress3 die design software is very useful for all die design including progressive, transfer, fineblank, & draw dies, as well as four slide tooling, etc. It provides an organized system, even between multiple designers for accurate & efficient design that can be virtually mistake-free if all steps are followed. This system has evolved over 30 years of development by listening to and acting on feedback from hundreds of die designers, tool designers and tooling engineers. Many designers find efficiency gains between 30 to 50% and more, in addition to dramatically minimizing development and debug time. At the same time they find their die design experience to be much more rewarding and enjoyable.

Tool Structure

Logopress3™ Die Design Software includes a powerful Tool Structure Assistant that allows you to quickly model the main die components. It is also very useful throughout the entire die design process when you need to insert additional plates or sub-assemblies.

You can very easily and very quickly insert a plate or a sub-assembly and then adjust its dimensions. The plates can be named at this point and material type and heat treatment can also be specified at the time of insertion. It also acts as a Mate Manager so that you don’t have to search the feature tree for mates.

- Component and sub-assembly insertion feature dedicated to the die design needs

- Customizable plates

- Customizable die sets

- Automatic mate management

- Customizable material database

- Customizable heat treat callouts

Standard Component Library

No die design software is complete unless it has a thorough Intelligent Standard Component Library. The Logopress3™ library not only inserts the component you select but also cuts every hole in each plate and automatically manages all mates.

It manages both millimeter and inch components and includes literally dozens of vendors that you are also able to add to. The only way to understand how powerful, user friendly, flexible, customizable, strong and complete it is, you must see it for yourself.

- Holes are cut and components inserted with one mouse validation click

- Standard Hole Wizard holes

- Automatically sizing of components

- Choice assistant

- Automatic patterning

- Edit definition

- Smart copy and paste function

- Customizable library

- Automatic mate management

- Automatic hole creation

- OpenGL preview

- Wire EDM hole management

- Dozens of custom and multi stepped holes - all hole chartable

- User defined custom components

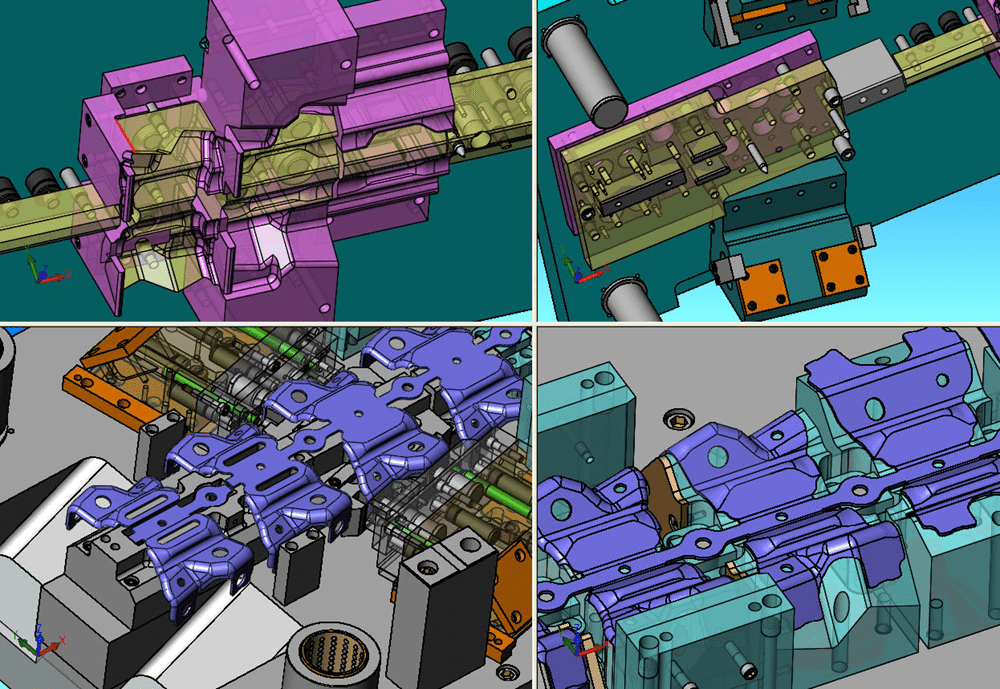

Punch Mounting

Logopress3™ also includes powerful features to "Mount" the cutting, bending and forming punches (cut all openings in all plates). Punch Mounting would be a huge amount of work without this dedicated feature since so many die components are involved which each needing different clearances. Logopress3™ easily manages this with only a few mouse clicks and dialog box settings. After you define the first one, Logopress3™ stores your preferences in order to save even more time for the next mounting.

If later on you decide to create an insert around your punch or die mounting, Logopress3™ offers you a dedicated feature to do this very easily, including the ability to automatically create a shim under the insert.

- Cutting punches

- Automatic plate recognition

- Bending punches

- Coining management

- Forming punches

- Cut all openings in all plates

- Clearance management

- Relief type management (tapered or stepped relief)

- Shoulder, heel, pedestal and roof management

- Locking tab management

- Editable mountings

- Store user defined preferences

- Punch mismatches/undercuts

- Corner relief options

DIE DEBUGGERTM

Eliminate mechanical design mistakes by running your die in a virtual tryout press. SolidWorks and other 3D design software can check for interferences between parts in the position they were designed in. But only Logopress3 has the ability to quickly define the complex motions of cams, pads, transfer systems, etc, and then check for interferences between these moving parts as the material feeds and the press cycles.

- Great for teaching new designers

- Great for wrapping your head around complex designs

- Can be done at any time once your tool assembly is saved.

- Can be used with designs from other programs, as long as SolidWorks can open them as an Assembly

Tool & Die Hole charts & Bill of Materials

Logopress3™ has multiple tools for automatically creating the 2D drawings for the 3D model, including automatic population of title blocks. These tools enhance the tools already in SolidWorks™ and include a specific and powerful Logopress3™ Hole Chart Feature as well as a specific and customizable Logopress3™ BOM. The Logopress3™ Smart Ordinate Dimensioning command makes dimensioning extremely fast.

Solidworks™ along with Logopress3™ make the creation of detail drawings very easy and fast, with considerable flexibility allowed for user preferences.

Logopress3™ takes full advantage of all of SolidWorks™ power and ease of use and includes many other dedicated tools based on our 25 years of experience that will make today's modern die designers much more productive. In the end, you will be much more profitable.

- Front side and back side holes in the same chart

- Automatic, complete, and very detailed description of every hole in addition to the X and Y data for each tag, tolerances and also the standard component going into that hole

- Many options for automatic sorting/sequencing of balloons

- Populates sizes of without needing reference dimensions

- Automatically sort/group upper, middle & lower parts as well as standard components