LogoPress Round Draw

LogoPress™ StripLayout module includes great and specific features and capabilities dedicated to Round Draw Parts.

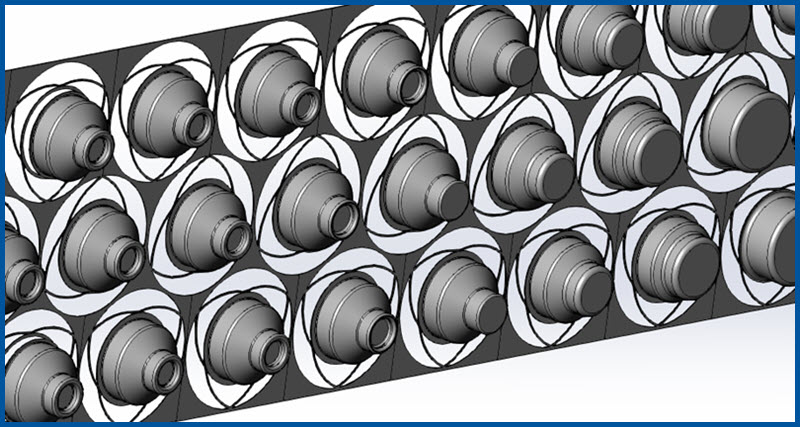

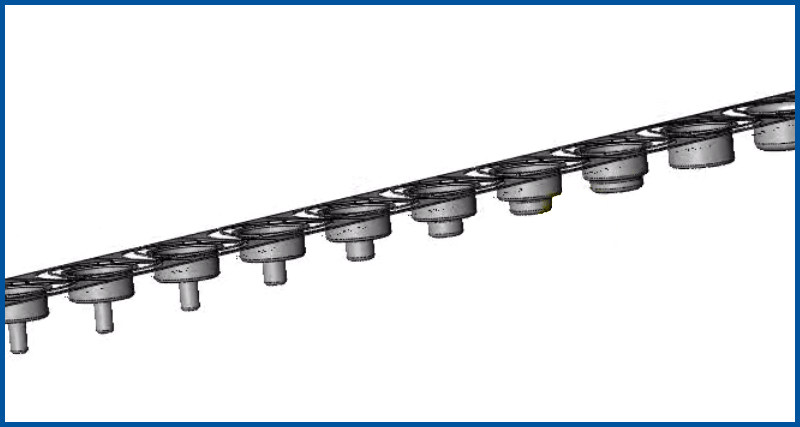

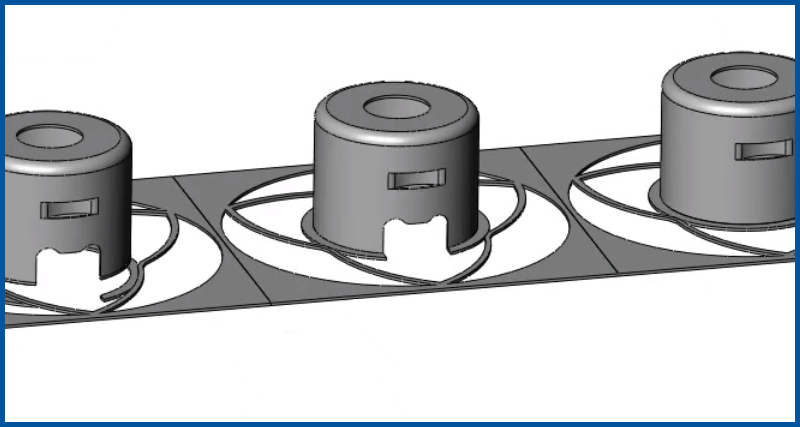

For those who have to manage these kinds of parts, this may mean saving several hours of work or even several days! Take a look at the pictures below. They speak more than a long explanation would, knowing that all of this is done in less than 5 minutes!

It’s also important to highlight that as everything is parametric, any changes can be done very quickly. In addition to that, you will find it very interesting to note that this is not newly developed technology, but rather has been well proven for over 20 years in our previous LogoPress 2D product as well.

Key functions

- Automatic computation of each intermediate stage

- Material type of drawn part automatically determines what draw reductions are used

- Draw reductions can be manually edited for each individual station

- Customizable computation database to include your experience and know how

- Automatic re-computation when changing a radius or a diameter

- Stripper pressure computation

- Automatic and customizable web management

- Graphical overlays of previous stations or subsequent stations

(6:22) In the video to the left we create a round drawn part from scratch that includes both a conical wall as well as a reverse draw in the bottom of the cup. During these six minutes, besides creating the part from scratch, we also process every draw station of the part and put it into a twelve (12) station strip, including stretch webs. We then turn it into a 3 out die in a matter of seconds.

(6:16) As in the video above, we create the part from scratch and then create a 16 station strip layout for this two step drawn part.

(9:17) The eleven (11) station strip layout below is created from an existing part with features in the side wall which makes things more complicated. That is the reason for this strip taking nearly ten (10) minutes. The finished part does not have a flange on it and along with the features in the side wall of the part, these things make the methodology in processing this strip unique from those in the videos above. Note that it would only take two or three minutes to add to add idle stations to any strip in the videos on this page.