Flatten

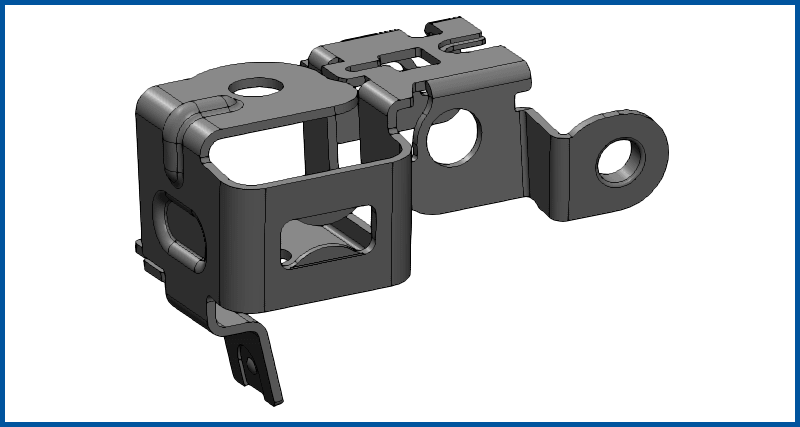

LogoPress Flatten includes two powerful tools for flattening DUMB, IMPORTED PARTS from any CAD system. Unbending by Steps can unbend dirty imported parts (without any special preparation), calculating the correct K-factor for the bend. Finite Element Analysis of complex formed parts can be performed using the Blank command, generating a flat blank, as well as thinning, stress and strain data.

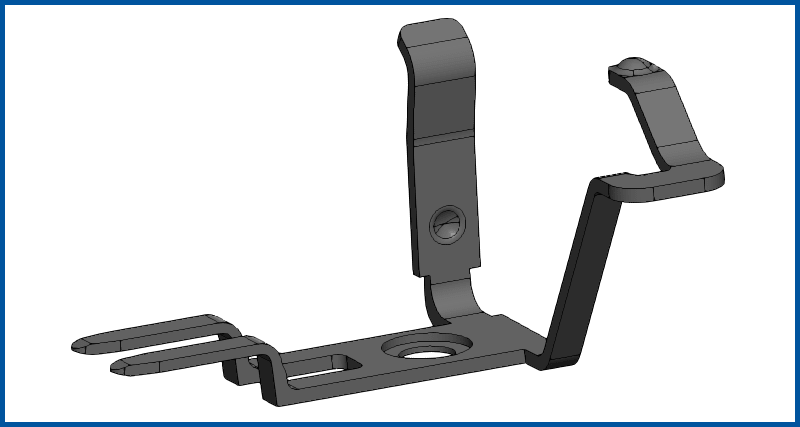

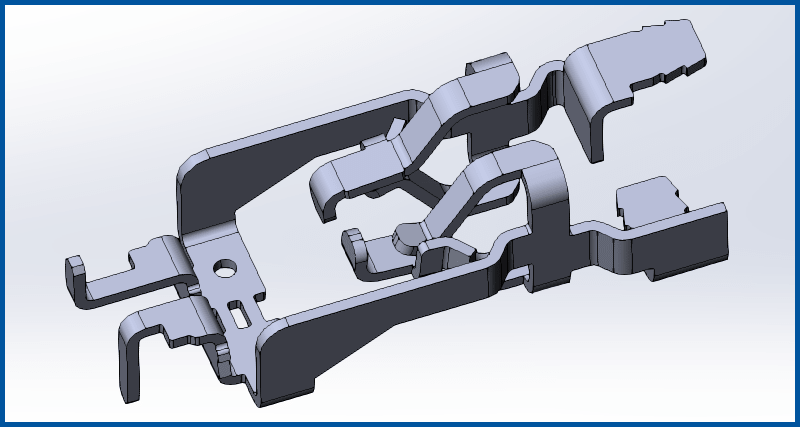

(1:56) This video is of a small section taken from of a large lead frame. This part would have taken a very substantial amount of time to remodel. But because of LogoPress robust Unbending capabilities, remodeling was not necessary to unbend it. The part has sharp corners on some radii, the material thickness is not parallel from side to side, there are coined areas, etc...

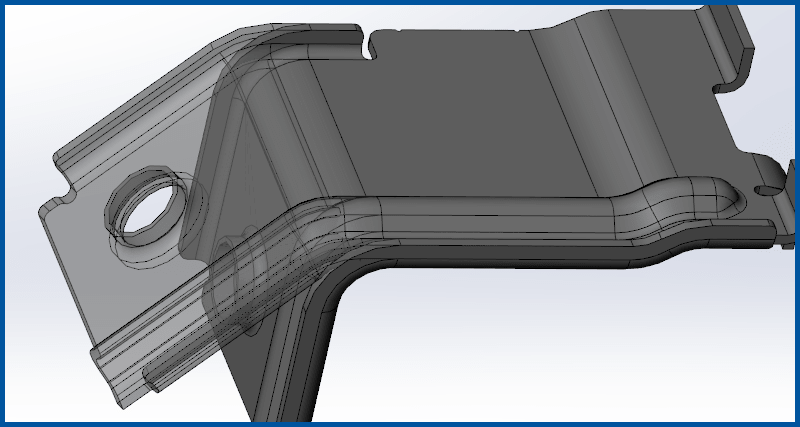

(5:09) This video is of a part that we designed a die for back in 2005. We subsequently wrote an article for MetalForming Magazine about the 3D die design process for it. We flatten and do forming analysis on the part using LogoPress BLANK, showing much of its functionality, including constraints, stress, strain, thinning, animation, etc...

(4:48) This next video demonstrates the LogoPress Unbending command "Blank for bent part" which unbends the entire part with one mouse validation click while automatically calculating the actual k-factor for each individual bend. We also demonstrate how you can tell when a part is "dirty" and thus SolidWorks Sheet Metal will not unbend the part. Finally we show a rough strip layout for the part.

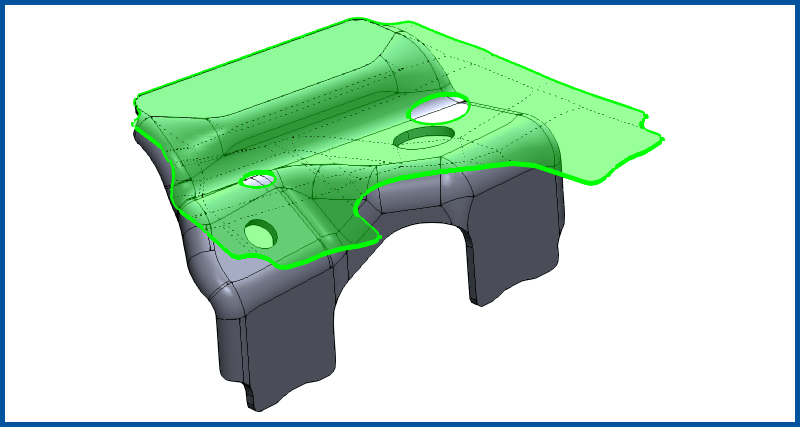

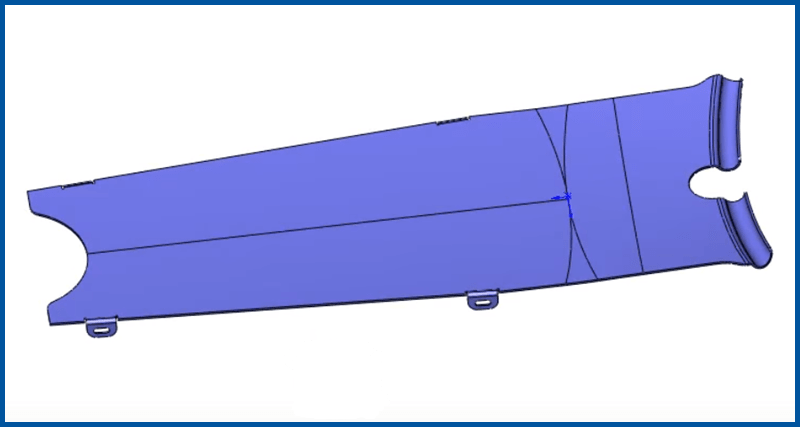

(6:47) In this video we demonstrate how to manage a part that is only a surface body, also known as a skin. It is not a solid body. It also has no flat surfaces to pick that are perpendicular to the forming direction. This makes the use of the SolidWorks Split Line feature necessary. Split Lines are very often used with LogoPress BLANK, especially with parts that are fairly symmetrical. We also demonstrate how to use these split lines as X and Y constraints and also show edge constraints, all of which lock down the geometry. We show the Inside edges sketch option, we preview the Mesh, Stress, Strain, Thinning, Contour points mapping and Animation. Finally, we point out the fact that LogoPress BLANK does not destroy or degrade what was good geometry. Your arcs and lines are still arcs and lines after flattening.