Strip Layout, Tool Design, Drawings, and BOM - from 2009!

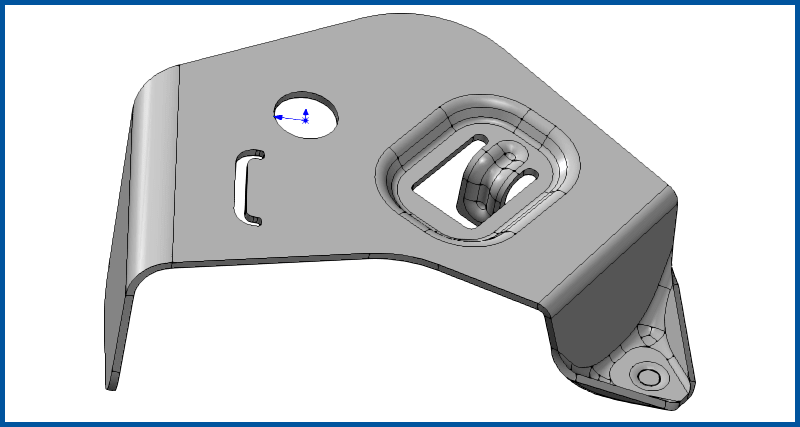

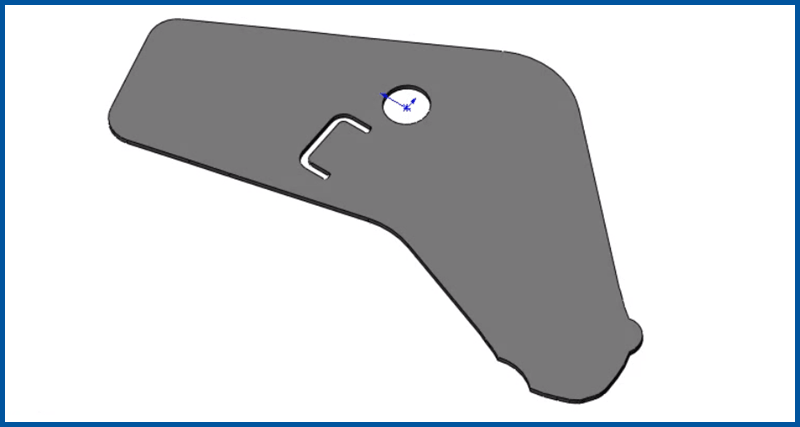

LogoPress StripLayout takes full advantage of solids. While you can integrate surfacing as well of course, users really appreciate the fact that when the strip is complete, it looks as if it came out of the die. This is especially important with coining and multiple thickness materials, but is also valuable with constant thickness parts. StripLayout includes robust tools for multiple parts in a strip, mirrored parts, blank nesting, Excel spreadsheet with quoting information, tonnage calculation, springback/overbend with automatic radius calculation, automatic internal punch creation, automated trim punch creation, etc...

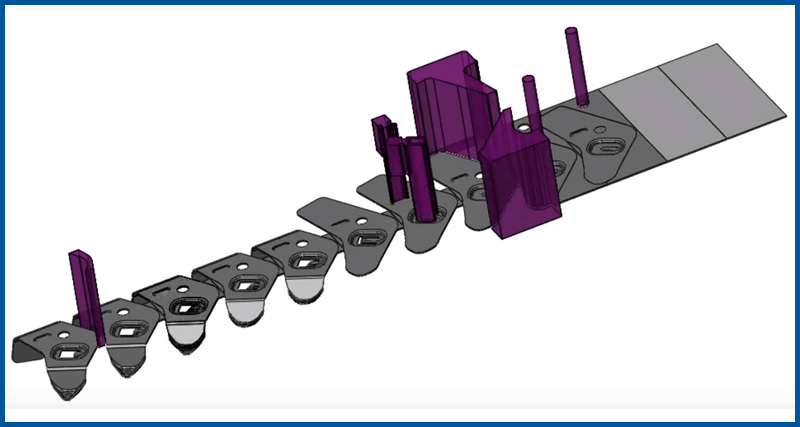

(8:19) This is an example of adding both 2D and 3D form punches to the strip assembly rather than adding them during the tool creation. The pros to adding them at this point are you can more easily communicate the strip to others with the form punches in the strip, you can more easily see yourself whether you have room for the form punches and finally, there is less clutter in the way because the tool isn't around the form punches.

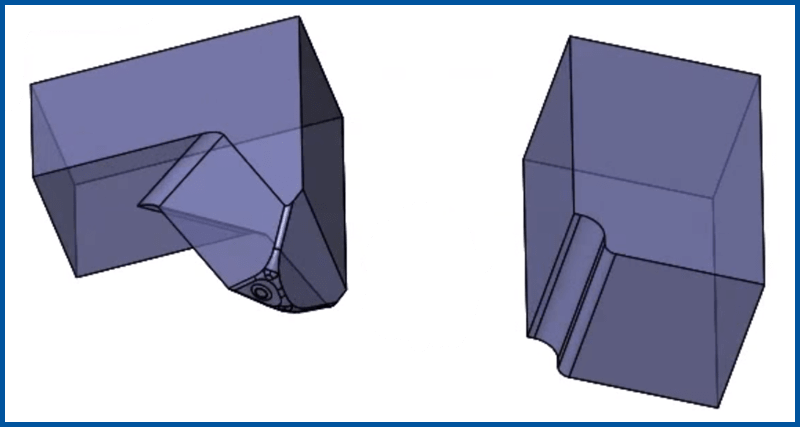

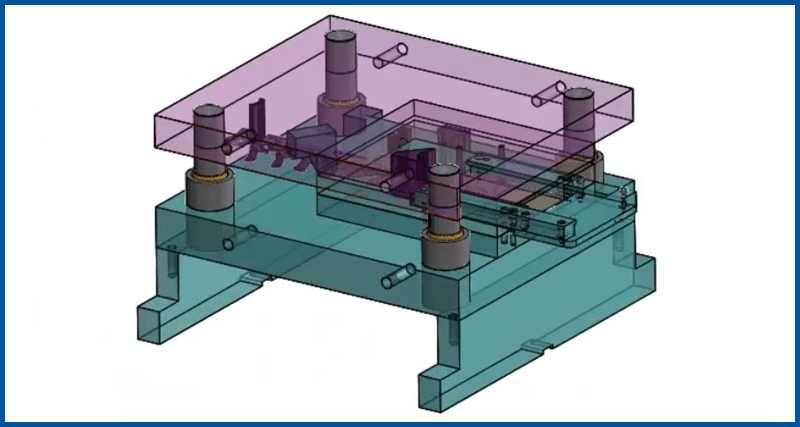

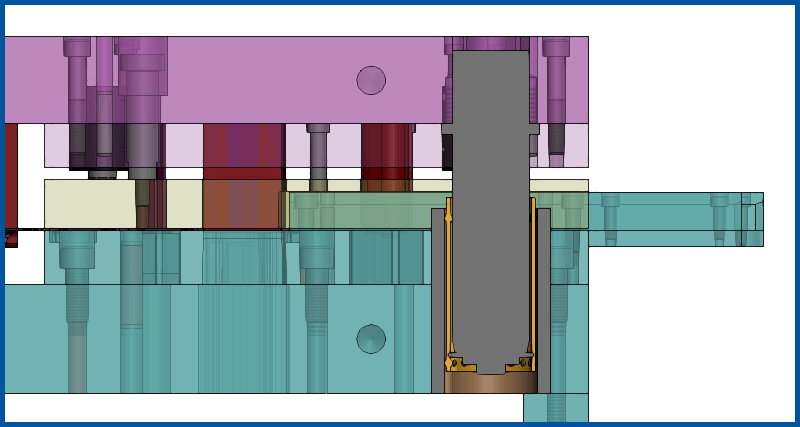

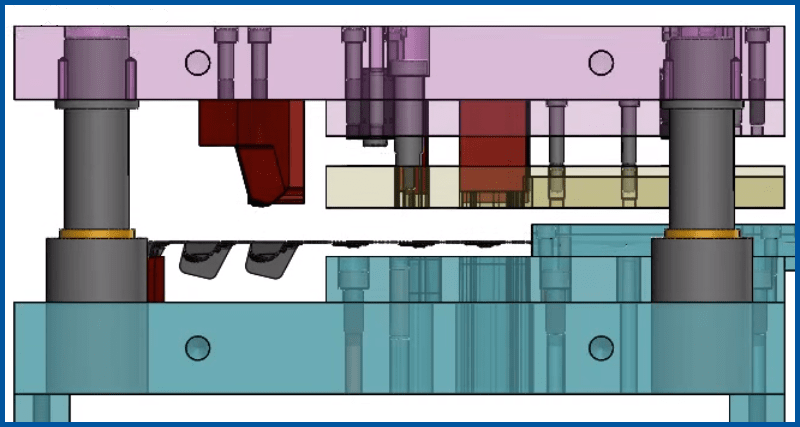

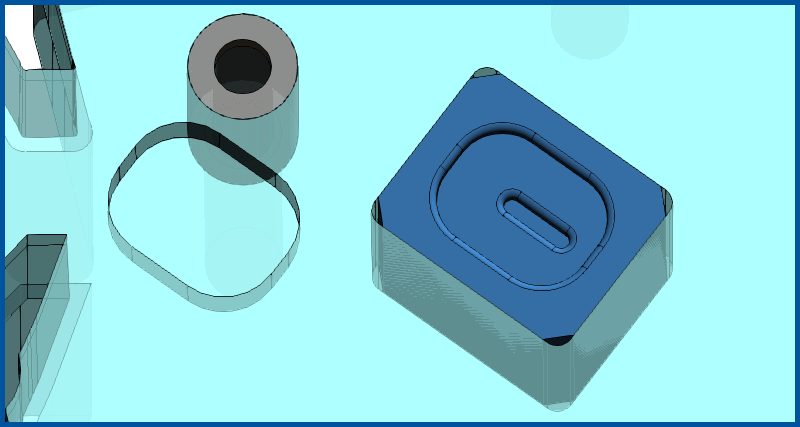

(9:12) LogoPress Tool Structure is used to automatically mate the strip assembly into the die assembly and then insert plates. LogoPress' "mate manager" is demonstrated. A stock tray with rails is adjusted in Tool Structure. Cutting punches are "mounted", that is, all holes are cut through all plates with proper clearances and punches that were in the strip are derived and inserted into the upper assembly.

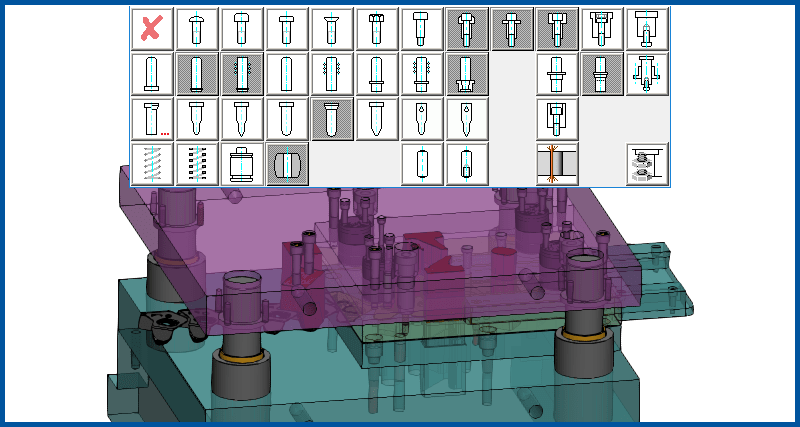

(9:31) Sketches merging tool is used. Standard components are inserted using 123GO Catalog Component Library including: Spool pad retainers, socket head cap screws, dowels and nitrogen cylinders. Cylindrical punches are mounted along with die buttons, cutting all openings throughout the die and creating components. Automatic patterning is demonstrated as is spring force computation center.

(6:19) Design review changes are made, including changing 3/8 screws to 1/2", counterboring them deeper and adding additional screws in a matter of a little over 60 seconds. Ball bearing demountable guide posts are changed to Danly type II demountable ball bearing posts in a matter of 1 1/2 minutes, including cutting all holes new and adding tapped holes around posts for clamps.

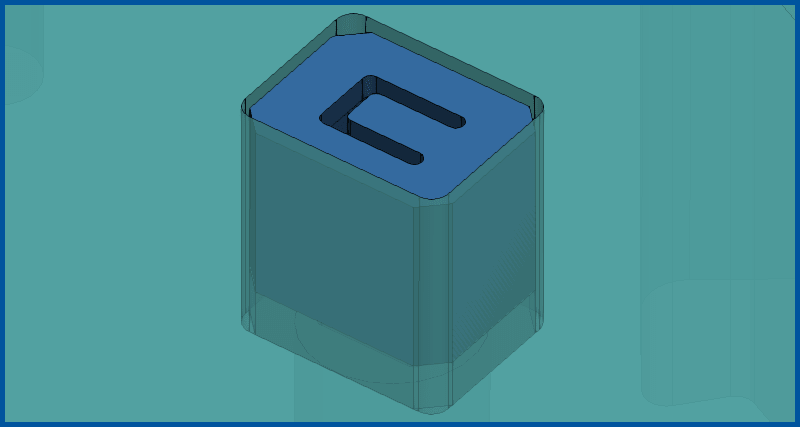

(9:57) The proper and important steps for updating flat blank geometry after development of the tool (or making any other changes to the part) are demonstrated in the video below. In this video, one edge is made bigger on the part and one smaller. Also, the legs of an internal U shaped cut are made longer by 0.125" on the dumb imported model that was received from the customer using the SolidWorks "Move face" command. Then, after activating the LogoPress command "Update the annex part used in the strip", the strip is automatically updated, as are the cuts through the die. (The cutting punch sketch sometimes needs manual editing.) This updating takes place in less than ten minutes.

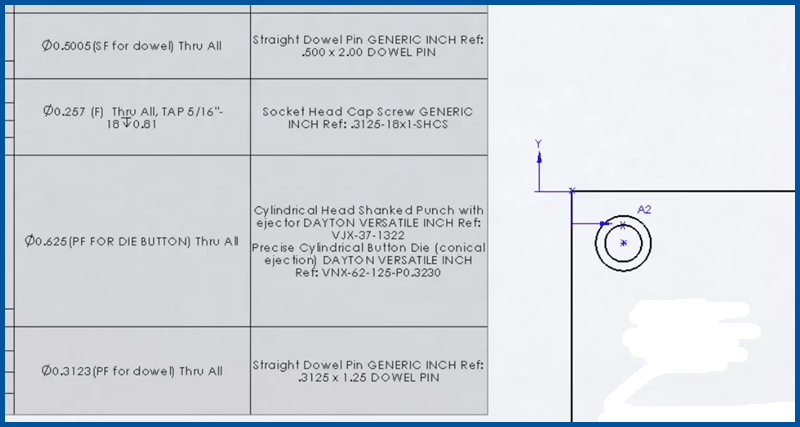

(1:53) The fact that most of the drawings are being created automatically in the background as you are modeling the die is demonstrated. A hole table is added to the die block and such things as notes in the hole table for "SF for dowel" and PF for die button" are automatically populated, due to LogoPress' 123GO Catalog Component Library - all of this in less than two minutes.

(9:57) A 3D form insert for the emboss is added to the die plate using the LogoPress "Add an insert" command. "Sketch fillet management" is demonstrated again. In slightly over two minutes, a 3D emboss form punch is created from scratch and all openings are automatically cut through the punch retainer and stripper with proper offsets. Wire EDM start holes are added (less dimensions) and the parametric nature of drawings is demonstrated as we switch windows back to the die block we had previously shown. We are automatically prompted with "The document has changed: do you want to update the tables? Hole Table 1" and when we answer Yes, the Wire EDM start holes are automatically added to the end of the hole table and labeled on the face of the die block in the drawing.

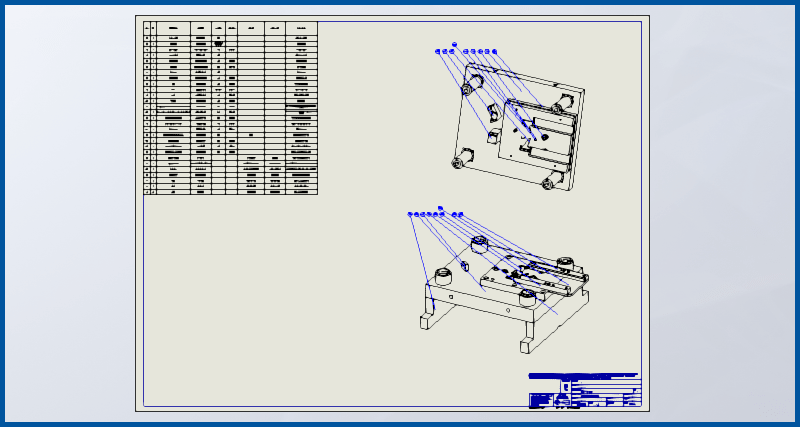

(8:58) The LogoPress BOM (Bill of Materials) is created and it is demonstrated that the drawing that will contain this BOM has been automatically generated in the background already, along with the title block being populated already. The use of SolidWorks Display states as well as SolidWorks balloons is demonstrated. The features of the LogoPress BOM are demonstrated including the fact that it uses an automatic bounding box to determine the size of parts, even on the 3D shaped punches. The LogoPress BOM is very flexible and allows several numbering schemes. The user can lock numbers at any time so that they don't get new numbers assigned. You can separate the purchased components such as nitrogen cylinders, punches, spool pad retainers, sensors, etc. and give them their own specific number range outside of the normal range of parts. Finally, the option to create balloons that are all in numerical order is demonstrated.