DIE DEBUGGER™ Tutorials

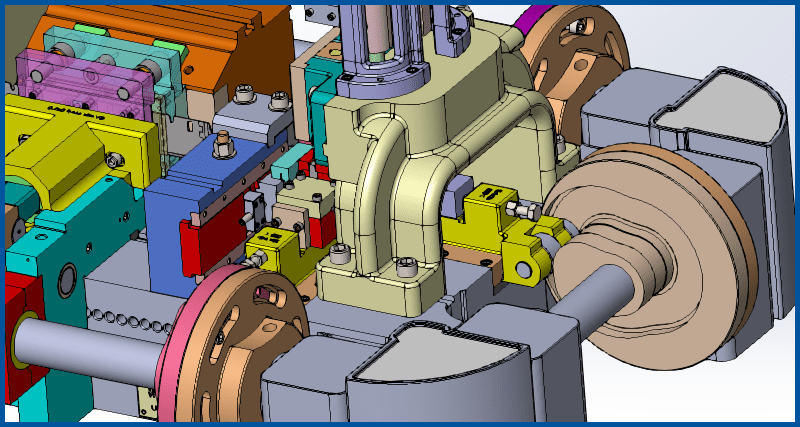

DIE DEBUGGER™ is very easy to set up. The user only needs to enter 3 basic die motions – press stroke, stripper travel, and strip lift – in order to apply motion to the die. Other motions such as lifters, cams, rocker forms, etc. can be defined using an intuitive interface in just minutes.

After the LogoPress motion is set up, the software can quickly check for clearance and feeding issues.

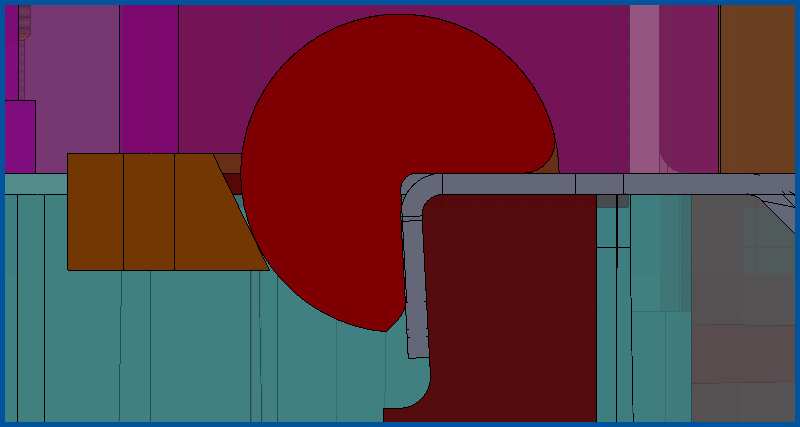

Basic Die Motion and Lifter Travel

(2:53) Apply basic motion to the die by entering just a few values and after this you can link lifter travel to the strip lift that you had previously entered. (If the strip was designed in LogoPress, it already knows the progression.) After this you can use a dropdown list to “Link” various things to existing values that have already been entered. Play video

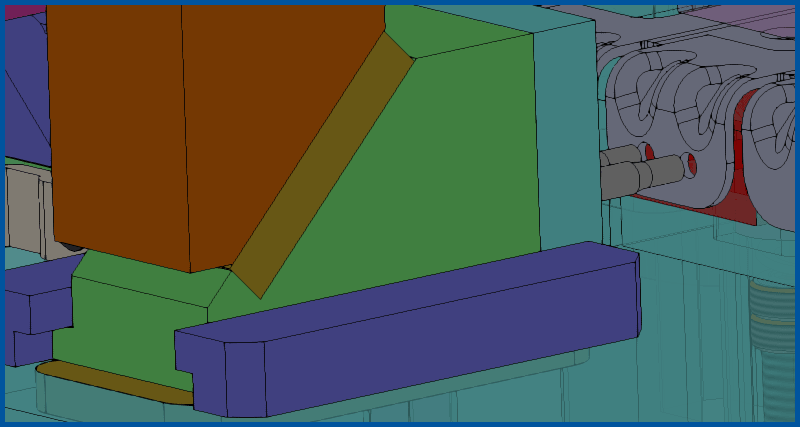

Linear Cam Pierce

(4:08) Quickly set up a cam (applies to cam piercing, cam forming, cam releases, etc.) in such a way that the contact that occurs in the press to drive the cam is duplicated on the computer screen. Play video

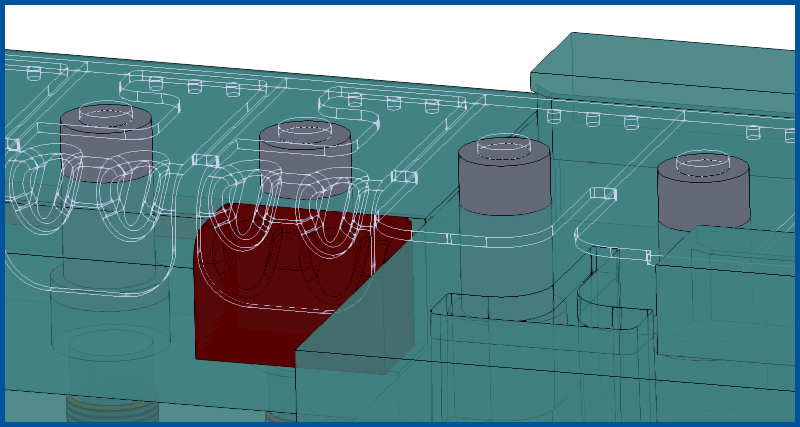

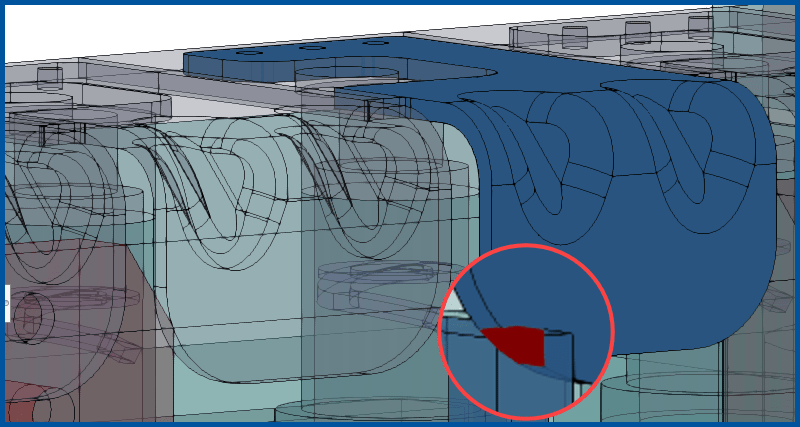

Interference Detection (Static and Dynamic)

(4:22) Catch design issues before the die design is released to the shop floor. Know before you go to the tryout press that you are lifting high enough, that you have not missed any clearance issues, etc.! Play video

Rocker Form

(6:00) Apply both rotational motion and linear motion based on contact. Play video

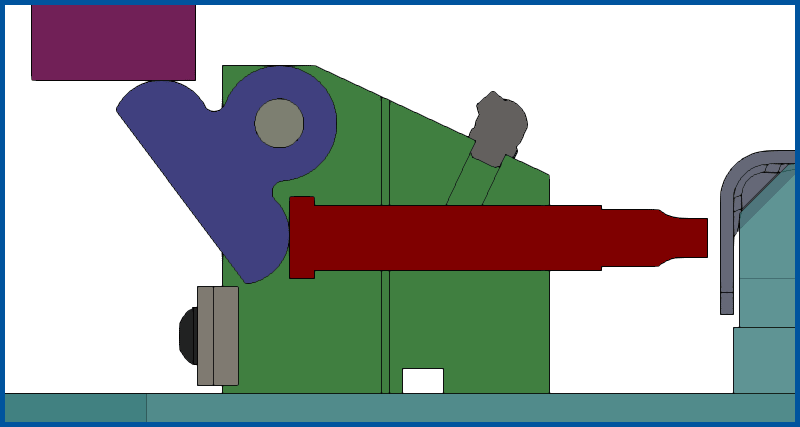

Cam and Slide

(6:45) Create linear motion driven by contact with a rotating cam. Play video

Rotary Bending

(5:29) Set up a rotary bender (a Ready Bender, for example) using contact based motion. Play video

Rotational Cam Pierce

(6:12) Set up rotational movement based on the contact between the driver and the back of the pierce punch. Play video