Logopress BLANK

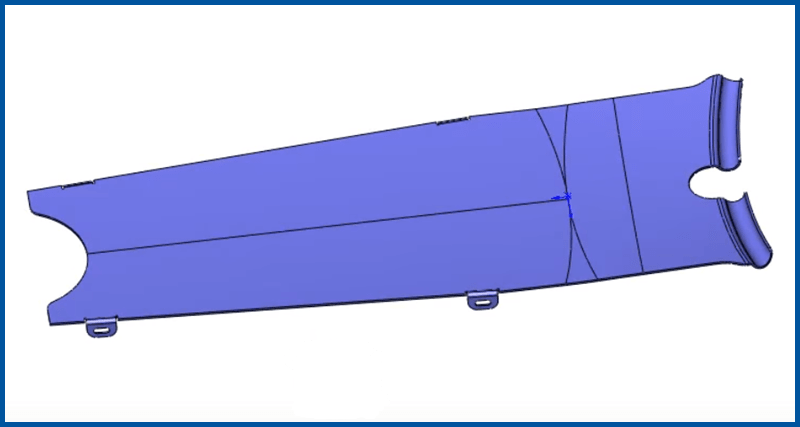

Logopress3 BLANK is a very economical yet accurate solution that allows the user to quickly and easily create the blank of complex 3D formed parts - also known as double-curved or automotive type parts. It also provides feedback on stress, strain, thinning, contour points mapping, etc.

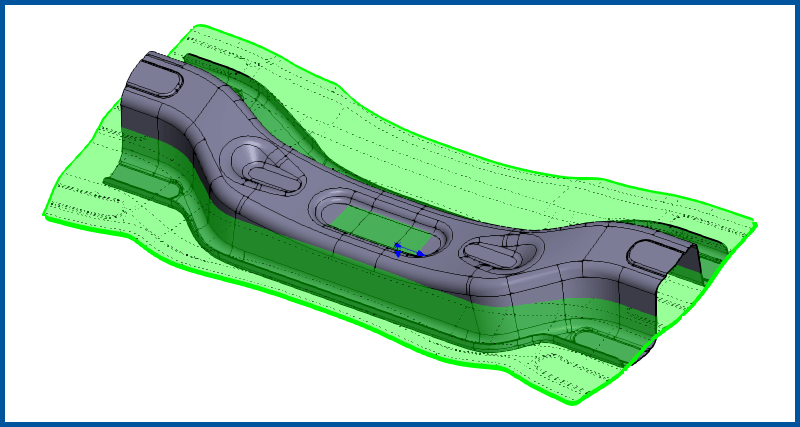

(2:35) In this first video you can see a typical complex automotive type part flattened and then animated by Logopress3 BLANK.

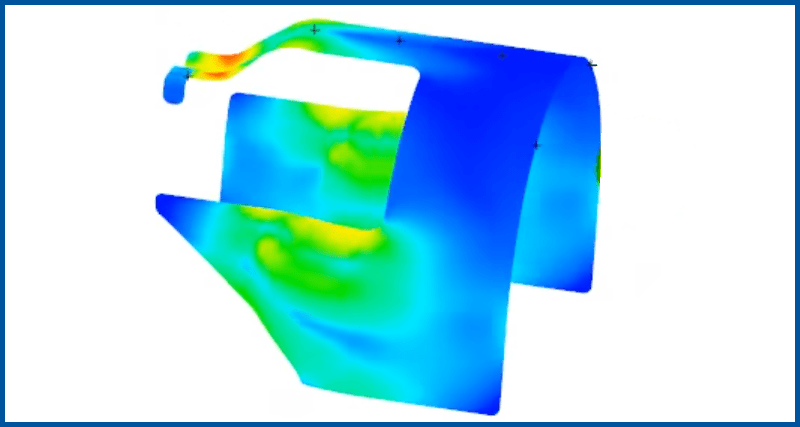

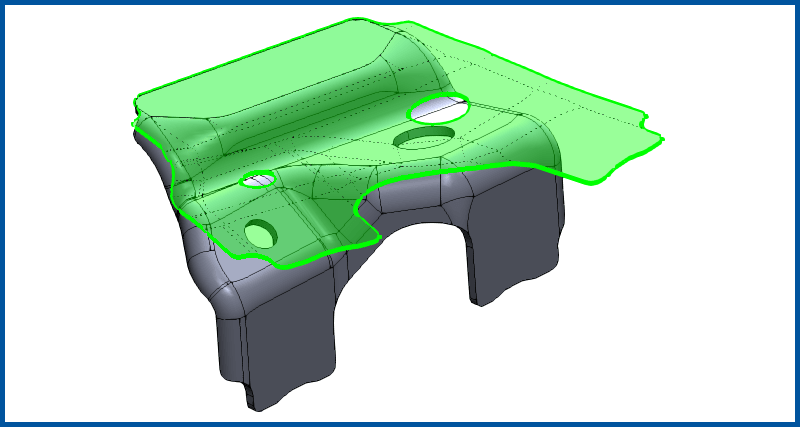

(6:47) In this video we demonstrate how to manage a part that is only a surface body, also known as a skin. It is not a solid body. It also has no flat surfaces to pick that are perpendicular to the forming direction. This makes the use of the SolidWorks Split Line feature necessary. Split Lines are very often used with Logopress3 BLANK, especially with parts that are fairly symmetrical. We also demonstrate how to use these split lines as X and Y constraints and also show edge constraints, all of which lock down the geometry. We show the Inside edges sketch option, we preview the Mesh, Stress, Strain, Thinning, Contour points mapping and Animation. Finally, we point out the fact that Logopress3 BLANK does not destroy or degrade what was good geometry. Your arcs and lines are still arcs and lines after flattening.

(5:09) This video is of a part that we designed a die for back in 2005. We subsequently wrote an article for Metalforming Magazine about the 3D die design process for it. We flatten and do forming analysis on the part using Logopress3 BLANK, showing much of its functionality including constraints, stress, strain, thinning, animation, etc...