Logopress Unbending

Logopress3 Unbending is able to unbend very "dirty" models and has additional capabilities that go far beyond standard SolidWorks Sheet Metal capabilities. Easily do moved center partial unbends, unbend bends that have strengthening beads/gussets, manage springback/overbends with automatic radius recalculation, manage non-constant thickness, etc.

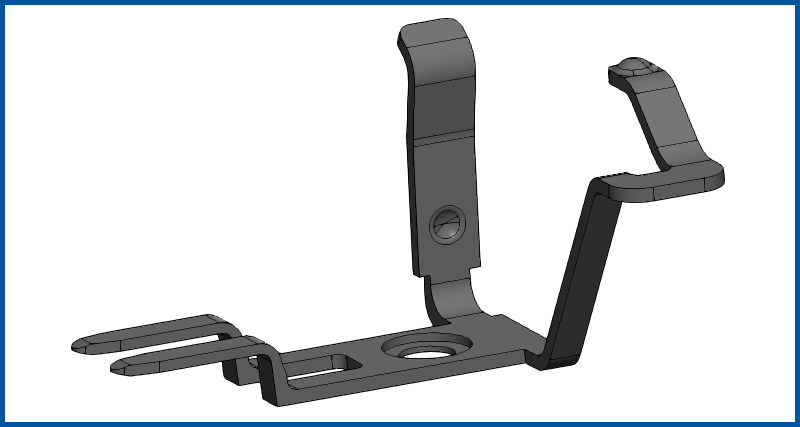

(1:56) This video is of a part that was originally a much larger lead frame when it was sent to us. Much of this part got cut away for this example. This part would have taken a very substantial amount of time to remodel. But because of Logopress3's robust Unbending capabilities, remodeling was not necessary to unbend it. The part has sharp outside corners on some radii, the material thickness is not parallel from one side to the other, there are coined areas, etc...

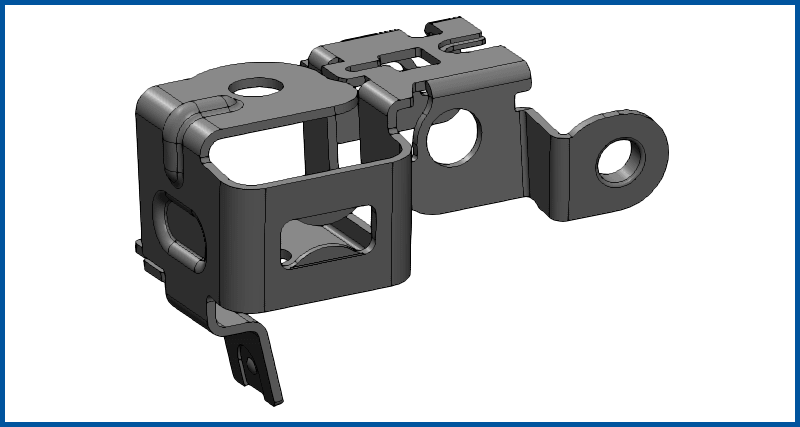

(3:22) The part in this first video is a complex folded "box" and it has many similarities to a part that one of our Logopress3 customers produced. It has a number of coined features on it along with a thin walled extruded hole that we process using Logopress3 Unbending.

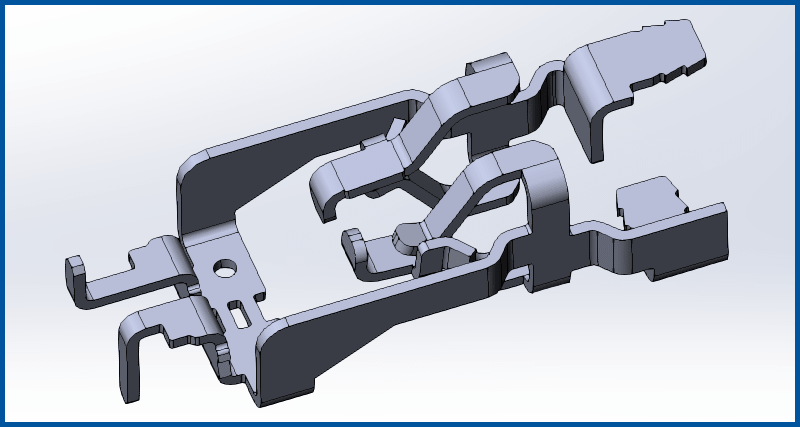

(4:48) This next video demonstrates the Logopress3 Unbending command "Blank for bent part" which unbends the entire part with one mouse validation click while automatically calculating the actual k-factor for each individual bend. We also demonstrate how you can tell when a part is "dirty" and thus SolidWorks Sheet Metal will not unbend the part. Finally we show a rough strip layout for the part.